Professors

-

Associate Professor

Ken SUZUKI -

Visiting Associate Professor

Wang Lei -

Assistant Professor

Zhang Qinqiang

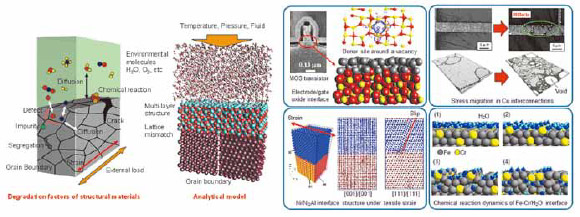

We have been conducting investigations of the interface integrity in various material systems such as nano-scale semiconductor devices, fuel cells, batteries, structural materials used for power plants. These complex material systems have the disordered atomic configuration in a thermodynamically metastable structure near a heterogeneous interface and then, the gradient of composition and strain always exists around the interface. Therefore the interface structure changes with time due to the gradient and thus, both the various properties reliability of the material system deteriorate easily. From this point of view, in order to design the interface integrity for ensuring the reliability of material systems, dominant factors cause the change in the interface structure under stress or strain are determined by using computational simulations and experimental methods. In addition, we are going to develop a method for analyzing the fluctuation of physical properties caused by atomic-scale damage and defects based on electronic- and atomic-level computational simulation techniques.

Explicating the fluctuation mechanism and design of the functional interface integrity based on atomic-scale simulations

Design of the functional interface integrity based on atomic-scale simulations

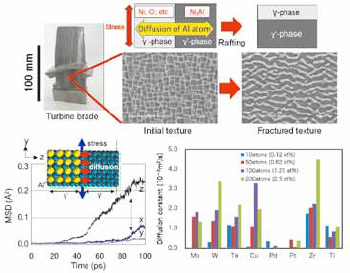

Fig.1 Explication of the fracture mechanisms of Ni-base superalloys at high temperatures under creep conditions by considering stress-induced anisotropic diffusion of component elements and effects of alloying element on diffusion

The aim of this research is to explicate dominant factors for improving the interface integrity in material systems. Atomic-scale simulations such as quantum chemical molecular dynamics are applied for the analysis. The mechanism of the change in the structure of the interface between stacked thin-films, precipitate/matrix interface and metal/environment interface has been studied by focusing on the strain-induced and accelerated atomic diffusion. To improve the performance and reliability of the macro and nano scale products and devices, we have been developing methods for optimizing the interface structure, material, and fabrication process.

Development of analytical methods for explicating the fluctuation mechanism of the interface structure and material properties

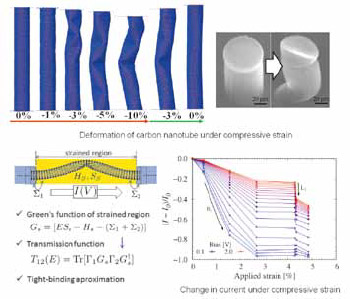

Fig.2 Development of a new method for analyzing electron transport properties using tight-binding based Green's function method and application to estimate current though carbon nanotube under under uniaxial compressive strain

The aim of this research is to develop new quantum mechanics based computational simulation methods for explicating the fluctuation mechanism of the interface structure and material properties. The influence of atomic and electronic structures of the heterogeneous interface on physical and chemical properties of material systems such as strength, corrosion resistance, thermal and electrical conductivity is discussed. In order to validate the analytical results and improve the simulation accuracy, the change in these properties are measured by using micro - and nano - scale measurement methods. We are going to develop a method for optimizing interface structure by the combination of computational simulation and experimental analysis.