Professors

-

Professor

(Research Cooperation)

Hideo MIURA -

Professor

(Research Cooperation)

Ying CHEN -

Visiting Professor

Isamu NONAKA -

Associate Professor

Ken SUZUKI -

Visiting Associate Professor

Wang Lei -

Assistant Professor

Theresa DAVEY -

Assistant Professor

Arkapol SAENDEEJING -

Assistant Professor

Zhang Qinqiang

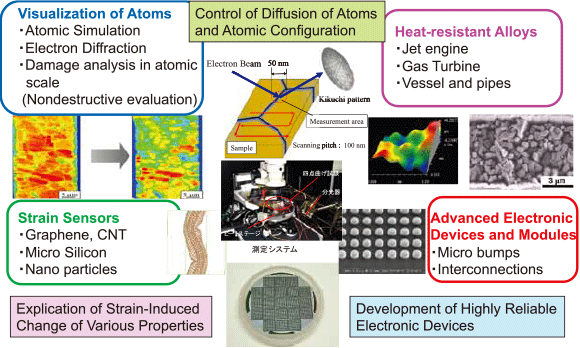

We have been developing methods for explicating the determinant factors of physical and chemical properties of various advanced materials used for infrastructures and electronic devices. Since the advanced functional materials consist of many elements and complicated micro texture, both their physical and chemical properiies should vary drastically depending on their micro and nano texture. The variation and/or fluctuation occurs due to diffusion of component atoms, and the diffusion is dominated by not only the gradients of temperature and composition, but also the gradients of strain, electromagneticfield, and so on. The main research topics of our laboratory is to develop methods for visualizing atomic configuration and diffusion of atoms, measuring physical properties in nano-scale, and predicting the residual lifetime of materials and structures under operation.

Fig.1 Strain Engineering in Nano-Scale

Development of Analytical Methods for Explicating Material Properties of Thin Film Materials

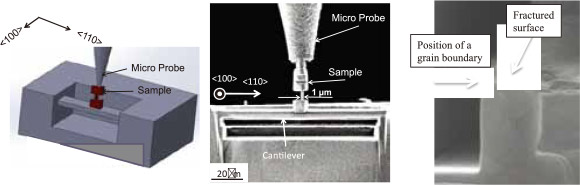

The aim of this research is to develop analytical and experimental methods for explicating the material properties of nano-structure and thin film devices. The effect of interface structure on the atomic bonding characteristics and band structure of electrons and holes is discussed. Quantum mechanics is applied for the analysis. The dominant factors, such as crystallographic defects, impurities, and diffusion of component elements around the interface, that cause the functions and reliability of nano and thin film materials to deteriorate, are determined quantitatively. To improve the electronic functions and reliability of thin film devices, we have been developing methods for optimizing the structure, material, and fabrication process of microstructures.

Fig.2 Measurement of Strength of a Grain Boundary as a function of its quality

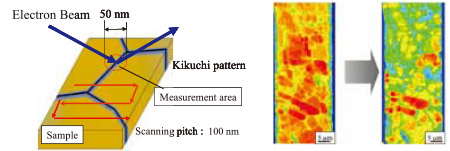

Development of Remote Non-contact Dynamic Strain Measurement Methods

The aim of this research is to develop a visualization method of atomic configuration around a surface of a material by using electron back-scatter diffraction analysis. Based on the Bragg’s law, the order of atomic alignment in the electron-beam-irradiated area was evaluated quantitatively. The distributions of damages in the material, such as vacancies, impurities, dislocations, and so on, and thus, the degradation process of a material due to the local diffusion of component atoms are visualized by nano-scale.

Fig.3 Visualization of the degradation process of a material due to the local diffusion of component atoms