Professors

-

Professor

Kazuhiro OGAWA -

Associate Professor

Yuji ICHIKAWA -

Assistant Professor

Chrystelle BERNARD -

Assistant Professor

Hiroki SAITO

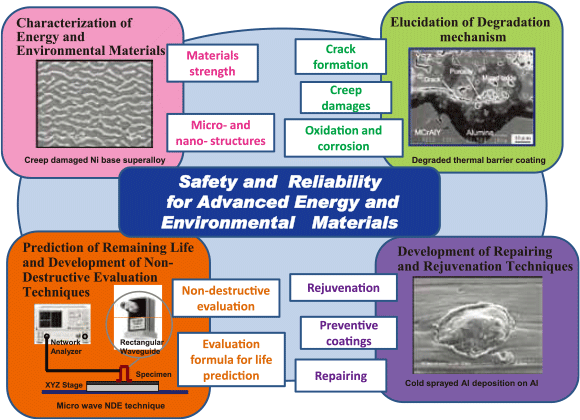

In this laboratory, researches for the safety and reliability of the materials and structures focusing on the control of micro-and nano-structures near the grain boundary/interface and on the strength evaluation of interface bonding which are promoted as the fundamental technology of development of advanced energy and environmental materials and structures. In particular, the physics and chemistry of fracture are studied by elucidating degradation and damage mechanisms of structural materials such as Ni base superalloys, thermal barrier coatings etc. The drastic improvements in efficiency of high energy conversion equipment demanded by society were realized through these researches, contributing to the reduction of environmental impacts.

Elucidation of Degradation Mechanisms and Development of Evaluation Techniques for Energy and Environmental Materials

The degradation, such as creep damages etc., of high temperature materials are evaluated using electrochemical techniques, nano-indentation techniques, and Auger electron spectroscopy etc. An understanding of the degradation mechanism in high temperature materials is aimed at by means of observation of micro/nano-structures.

Development of a Rejuvenation Technique Resulting in Longer Life Times for Energy and Environmental Materials

Rejuvenation heat treatment technique that renders the recovery of creep damaged high-temperature materials, such as Ni base superalloys, is being developed. Evaluation of the effectiveness of the rejuvenation and elucidation of rejuvenation mechanisms by small punch creep tests, ultra-micro indentation tests, observation of micro/nano-structures, and elemental and compositional analyses are also being performed.

Development of Room Temperature Bonding Technique for Bulk Metallic Materials

The room temperature bonding techniques using Surface Activated Bonding (SAB) method is being developed. In this technique, the oxide films are removed and material surfaces are activated by a fast atom beam (FAB). Subsequently, the activated surfaces are bonded under high vacuum at room temperature. The SAB bonded materials do not have heat affected zone (HAZ), which can induce degradation and damages of materials. Therefore, the SAB is expected as next-generation bonding technique for bulk materials.

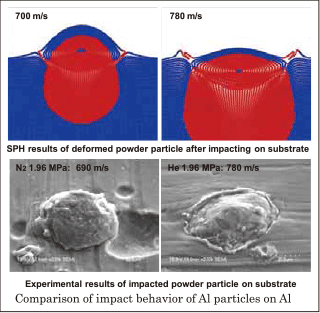

Development of Innovative Repairing and Coating Technique for Metallic and Ceramic Materials by Means of Cold Spraying

Establishment of innovative repair technique and coating using cold spraying and health diagnostics for cold sprayed deposition are carried out. Moreover, in order to evaluate the deposition mechanism and compatibility between substrates and particles based on scientific basis, micro-and nano-structure observation and smoothed particle hydrodynamics (SPH) approach are conducted for several deposition conditions.